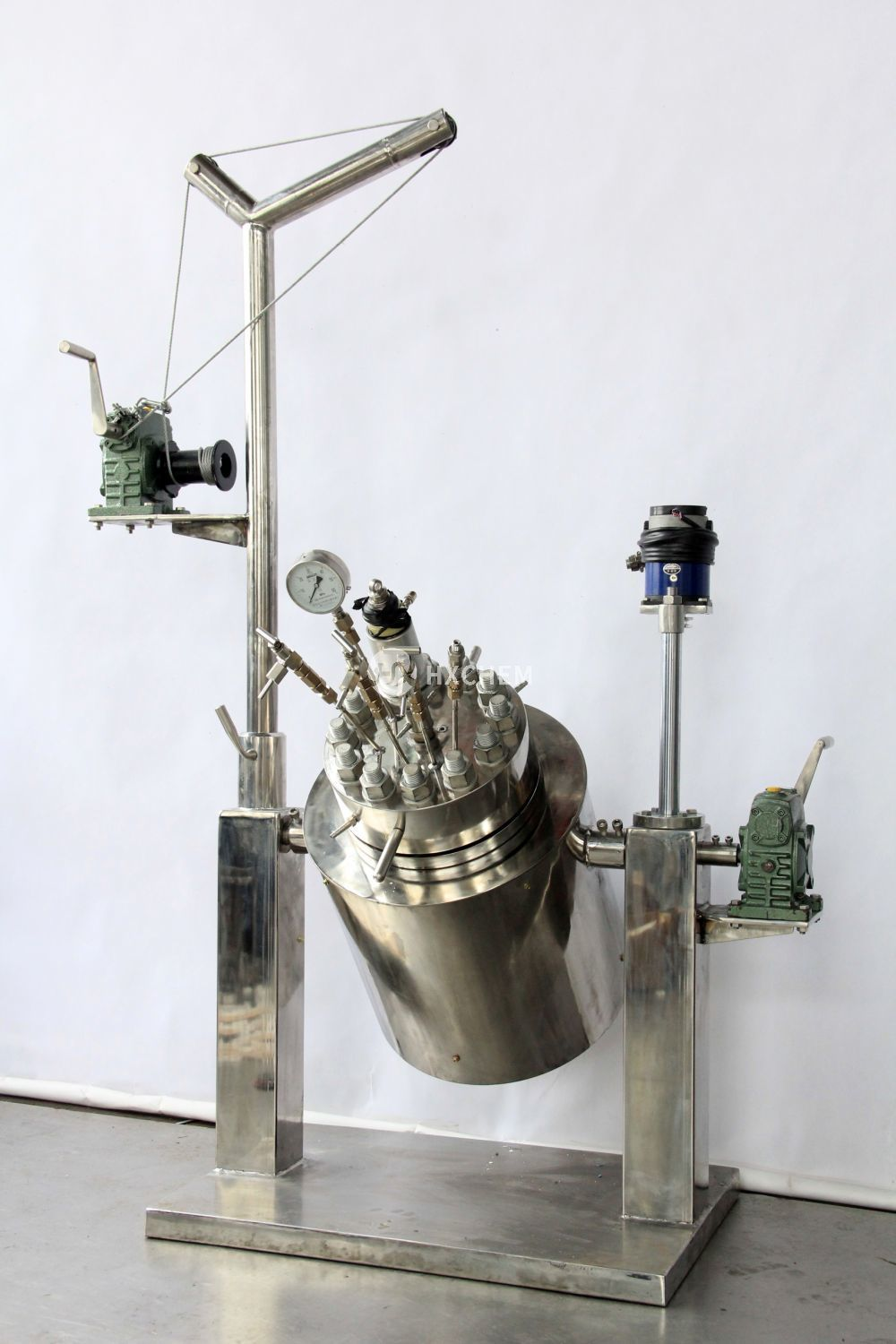

Lò phản ứng hàng loạt phòng thí nghiệm đóng cửa bằng bu lông 5L 200bar

Thể tích lò phản ứng: 5,0 lít Áp suất tối đa: 200 bar Nhiệt độ: 20 °C đến 300 °C Vật liệu: Thép không gỉ 304/316 Đặc điểm: Thân bình có thể nghiêng Nắp trên có thể nâng lên

- HXCHEM

- TRUNG QUỐC

- 20 ngày sau khi thanh toán

- 30 BỘ MỖI THÁNG

Chi tiết

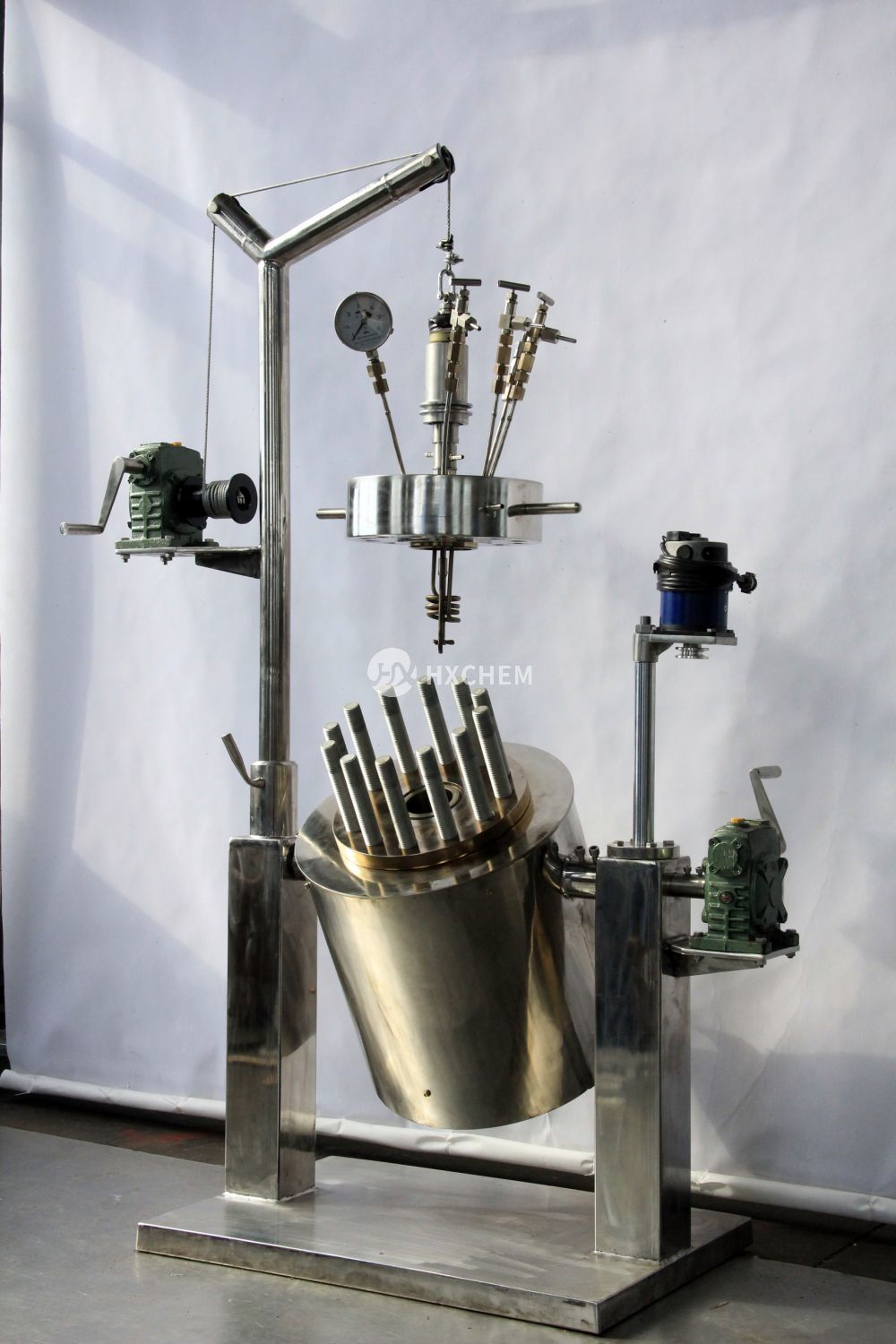

Floor stand bolted closure laboratory pressure reactors

Top cover lid manual lifting & Vessel body rotation

Reactor volume: 500ml, 1liters, 2liters, 5liter

Maximum Pressure: 0-350 bar

Temperature: 20 °C to +400 °C

Material: Stainless steel 304/316, C276, Titanium, etc

Features: Vessel body can be tilting ; Top cover lid can be lifting & lowering

Other materials, pressures & temperatures are available.

Features

High temperature and high pressure design

Flat cover lid: Lifting & lowering

Closure type: Flange type with bolts closure

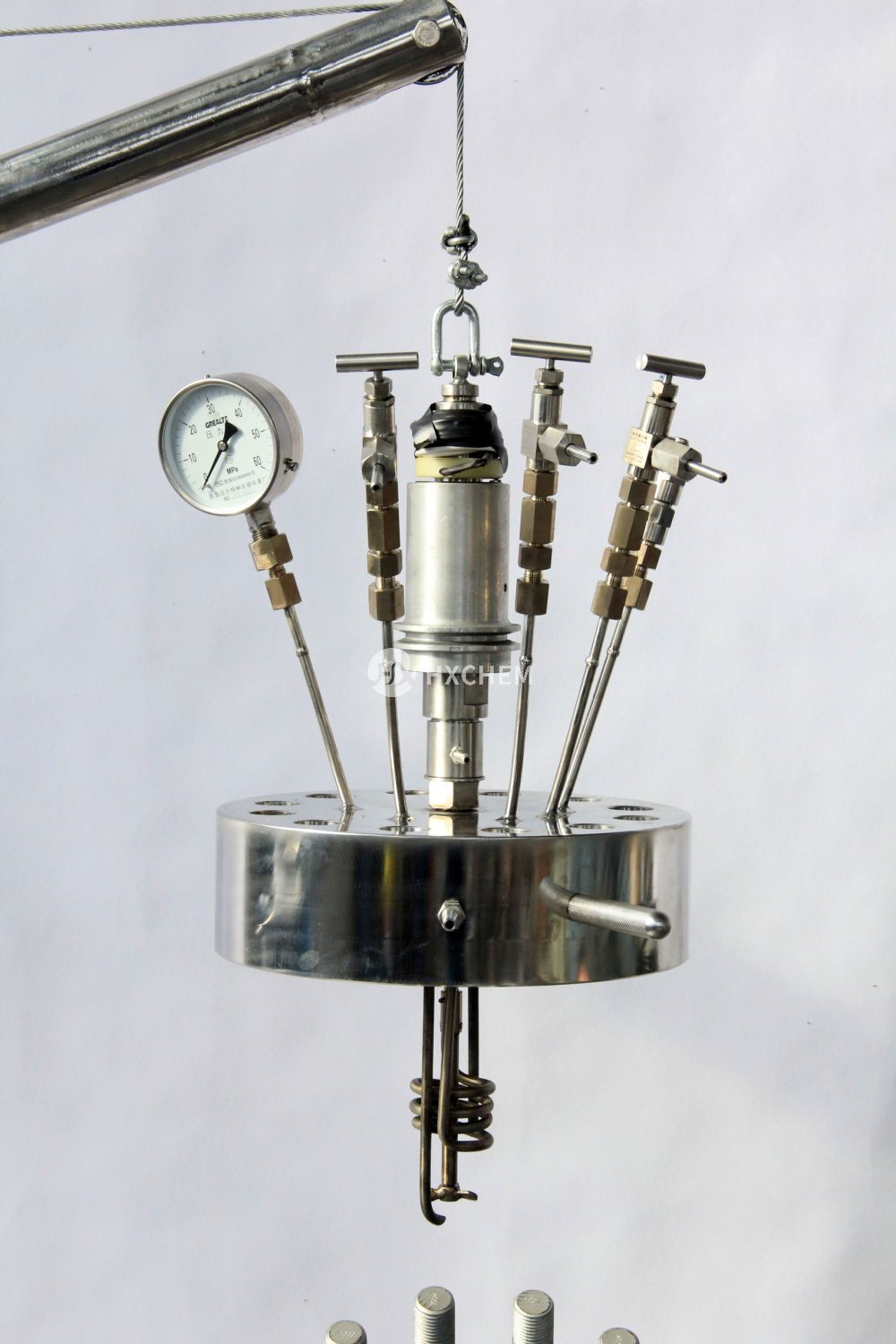

Shaft seal: Magnetic coupling drive

Reactor vessel: Tilting

Control: PID temperature and stirring speed control.

Standard specfications

GSH lifting reactor standard specification table.

| Model No. | GSH-5 | GSH-10 | GSH-20 | GSH-30 | GSH-40 | GSH-50 |

| Nominal Capacity | 5liters | 10liters | 20liters | 30liters | 40liters | 50liters |

| Max Working Pressure | Standard 100bar; Max pressure up to 250bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-750rpm | 0-500rpm | ||||

| Motor Power | 600W | 600W | 1.1kW | 1.5kW | 1.5kW | 3KW |

| Heating Power | 4kW | 9kW | 9kW | 12kW | 12kW | 15kW |

| Closure | Flange bolts closure/ Clamp closure | |||||

Lifting & lowering | Manual crain lifting/ Electric crain lifting | |||||

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Electric heating or Jacket heating | |||||

| Cooling | Internal spiral coils(Optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Impeller (Optional) | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||

Product Details

Applications

These reactors are used in many branches of chemical technology. Catalytic Hydrogenation with its associated catalyst development and testing is certainly one of the principal applications of these reactors with their excellent three phase mixing designs. Polymer development is another major area of application. Additionally, the vessels have been used extensively in hydrometallurgical applications. Hydrogenation, Catalyst Screening / Testing; Polymerization; Styrene Butadiene; Alkoxylation; Distillation; Ethoxylation; Hydrocracking; Dehydrogenation; Oxidation; Fischer TrophCarboxylation; Fluid Catalytic Cracking; Biojet Fuel production; Crystalization.

Related Product